Informational

Forging Process

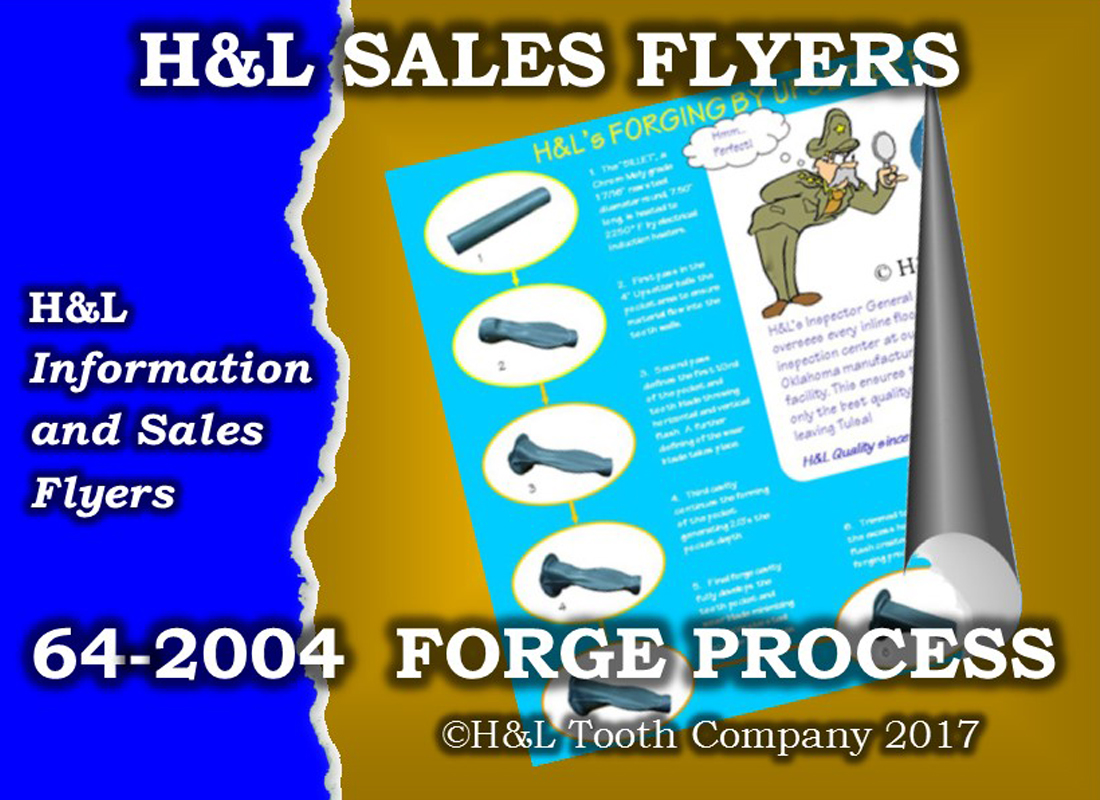

230SP Forged by Upsetter Process: H&L one page flyer, 64.2004 shows the forge process.

The “BILLET”, a Chrom-Moly grade raw steel diameter round billet is heated to 2250º F by electrical induction heaters. The billets first pass in the Upsetter, balls the pocket area to ensure material flow into the tooth pocket walls. Billet’s second pass defines the first 1/3rd of the pocket and tooth blade with horizontal and vertical flash. A further defining of the wear blade takes place. Billet’s third cavity continues the forming of the pocket, generating 2/3’s the pocket depth. Final forge cavity fully develops the tooth pocket and wear blade, minimizing the excessive steel into the flash areas. Then it’s trimmed to remove the excess horizontal and vertical flash created by the forging process. Creation of the Flexpin attachment holes are done on hydraulic punching machines exclusively constructed by and for H&L in the late 1960’s. Tooth finishing starts with the de-burring of the remaining flash materials and prior to heat treating. Heat treatment consists of quench and temper for an end result of 514BHN in hardness.

The 230SP is then painted H&L Blue and branded as FORGED MADE IN THE USA!

CLICK “DOWNLOAD” to view or print PDF file.